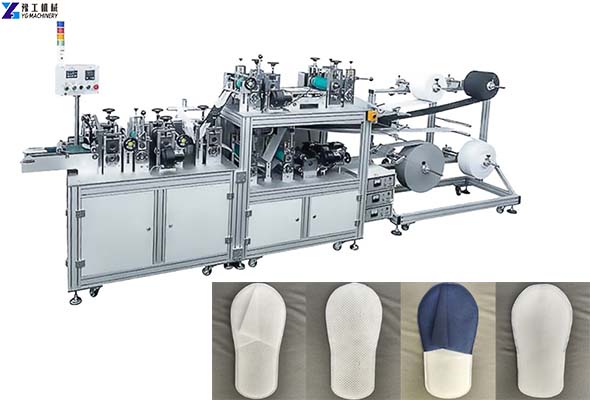

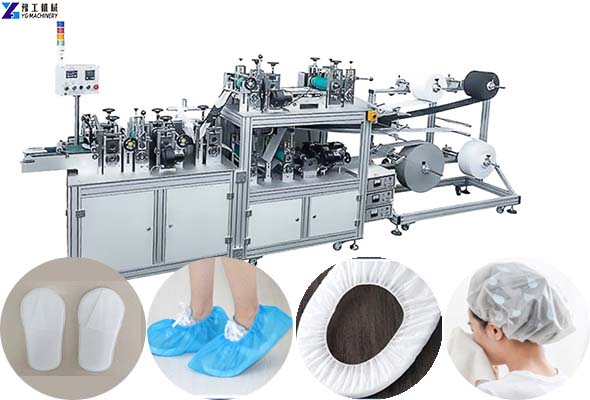

The disposable slipper making machine adopts ultrasonic welding technology to make disposable slippers for hotels. From feeding to cutting, embossing welding, rolling, and cutting finished products, the whole process is automated. The disposable slippers produced have no burrs, the finished product is beautiful, the size is consistent, and the stitching is firm. This disposable slippers machine for hotels is not only capable of producing slippers, but it can also produce gloves, pillow covers, toilet covers, PE shoe covers, finger covers, and many other products through custom molds. If you are interested in this multifunctional slipper making machine, please contact us.

Final Product Display

Hotel Slipper Making Machine Youtube Video

Applicable Raw Materials

This disposable slipper making machine is widely used in the processing of various materials. It can process non-woven fabrics, pearl cotton, dust-free cloth, nylon cloth, thermoplastic film, PE, and other materials. Through different raw materials and molds, it can produce various products such as disposable slippers, shoe covers, insoles, toilet seats, gloves, and so on.

Parameters of Disposable Slipper Making Machine for Hotel

| Model | YG-500 |

| Size | 5.24*0.99*1.63m |

| Voltage | 220V 60HZ |

| Air pressure | 7KG/CM² |

| Rated power | 6.8KW |

| Load power | 5.5KW |

| Ultrasonic power | 1.5KW*3 |

| Production Speed | 60~100pcs/min |

| Energy used | 7KW/H |

The above are the parameters of the disposable slippers machine, which can produce 60~100 slippers per minute. You can change different molding molds to produce different molds or disposable shoe covers, gloves, and other products.

Disposable Ultrasonic Slipper Making Machine Advantages

- Thickened body design. The machine is durable and of good quality.

- Automatic running. The disposable slipper making machine adopts intelligent automatic operation, saving manpower and material resources.

- A good after-sales service. YG nonwoven disposable slippers machine manufacturer warranty for one year. If there is any problem during the warranty period, we will quickly solve the problem for you.

- All functions are carried out in an orderly manner. Each part has its own function, and each function is carried out in an orderly manner, which is simple and easy to use.

- Servo drive, high degree of automation, high stability, low failure rate, and low noise.

Disposable Slipper Machine Details Display