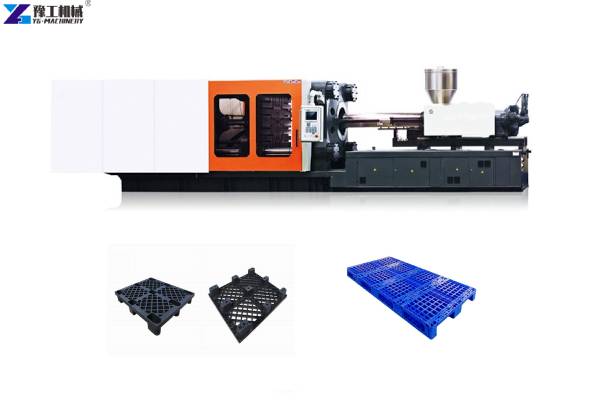

The plastic pallet making machine (pallet injection molding machine) is a special equipment for making goods turnover tools in logistics or warehousing. With the rapid development of the logistics and warehousing industry at home and abroad, plastic pallets have become indispensable tools for the transportation and storage of goods. The plastic pallet making machine can produce plastic pallets that meet the transportation of various goods by changing the plastic pallet molds. For example, the surface of the appearance is flat and grid-shaped, and the bottom is a tray with various structures such as Sichuan characters, Tian characters, seven corners, and nine corners. In addition, YG also has a plastic chair making machine, plastic garbage bin making machine, plastic toy manufacturing machine, etc.

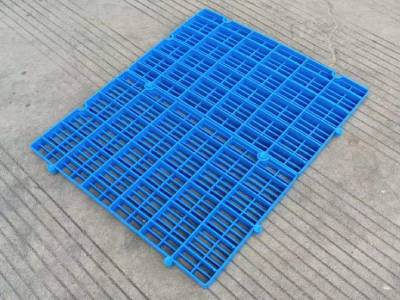

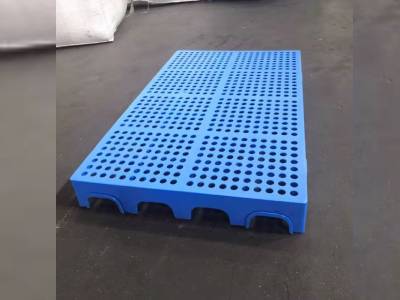

Finished Plastic Pallet Display

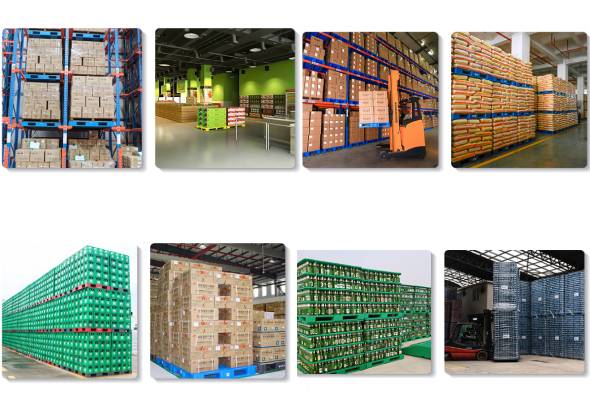

Application of Plastic Cargo Pallets

Plastic pallets are an indispensable tool for cargo transportation and storage. Plastic pallets are consumables and at the same time recyclable tools. Compared with wooden pallets, steel pallets, and paper pallets, it has a very high-cost performance. There are various forms of injection-molded pallets, which can not only meet the transportation needs but also meet the storage needs of products from all walks of life. Therefore, injection trays have a very wide range of applications. It is widely used in many industries such as food and beverage, chemical medicine, warehousing and logistics, clothing, paper making, electronic appliances, tobacco, automobile, import and export trade, etc.

Plastic Pallet Manufacturing Machine Parameters

| Injection device | Screw diameter | mm | 140 | 150 | 160 | 180 |

| Screw aspect ratio | L/D | 22.4 | 20.9 | 19.6 | 20 | |

| Injection volume | cm3 | 11083 | 12723 | 14476 | 24798 | |

| Injection weight | g | 10085 | 11578 | 13174 | 22566 | |

| injection pressure | Mpa | 154 | 135 | 120 | 118 | |

| Clamping device | Clamping force | KN | 20000 | |||

| Template stroke | mm | 1680 | ||||

| Die thickness | mm | 700-1600 | ||||

| Inner distance of guide post | mm | 1650×1550 | ||||

| Ejection force | KN | 406.9 | ||||

| Ejection stroke | mm | 450 | ||||

| Other | Motor Power | KW | 55+55+55 | |||

| Heating power | KW | 95 | ||||

| Oil mercury pressure | Mpa | 16 | ||||

| Dimensions | m | 16.4×3.6×4.3 | ||||

| Machine weight | T | 148 | ||||

| Die positioning ring diameter | mm | Φ315 | ||||

| Nozzle Ball Radius | mm | SR20 |

Plastic Pallet Injection Molding Machine Advantages

- Energy saving: Servo motors are used to directly drive each running structure, which not only improves production efficiency but also improves energy utilization.

- Stable injection performance: Various dynamic technical parameters are basically not disturbed by external factors, and the injection performance is stable.

- High Efficiency: The use of servo motors greatly improves the responsiveness of the system. In the process of mold opening, it can be ejected at the same time, and the film can be closed at the same time during the plasticization process, which greatly improves production efficiency.

- Multiple styles: There are many styles and sizes of finished products, and users can customize the injection tray mold according to their own needs.

- High performance: The plastic pallets produced have high performance, with anti-collision, anti-drop, anti-oxidation, low-temperature resistance, and impact resistance.

Plastic Pallet Making Machine Details Display