The bouffant cap making machine can adopt the ultrasonic heat sealing method, and use PE or non-woven raw materials to make shower caps. The disposable shower caps can be used in homes, restaurants, hospitals, or other dust-free environments. Plastic (non-woven) shower cap machines can replace different molds to produce bubble caps of various specifications such as 17, 18, 20, 21, etc. The bouffant cap machine has a high degree of automation, and can automatically realize the operation processes of feeding, forming, counting, and receiving.

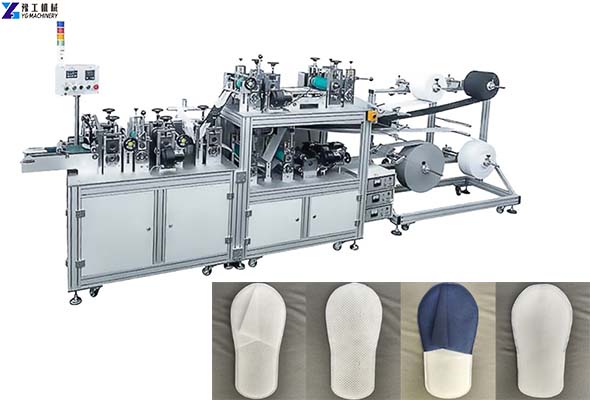

Produced Bouffant Cap Display

Disposable Bouffant Cap Making Machine Parameters

| Power supply | 220V |

| Output | 3kw |

| Size | 17’,18’ |

| Productivity | 0~120pcs/min |

| Dimension (L×W×H) | 3800*800*1100mm |

| N.W (kg) | 500kg |

Detailed Configuration Sheet

| No. | Name | QTY |

| 1 | Main motor 1.5KW | 1pc |

| 2 | Embossing roller | 3pcs |

| 3 | Ultrasonic horn | 3pcs |

| 4 | Ultrasonic system | 3sets |

| 5 | Transistor | 3sets |

| 6 | Capacitance | 3 sets |

| 7 | Inverter | 1pc |

| 8 | Contactor | 1set |

| 9 | Relay | 1set |

| 10 | Switch | 1set |

| 11 | Proximity sensor | 3pcs |

| 12 | Pulling Roll | 2pcs |

| 13 | Cold knife | 1set |

| 14 | Folder device | 2sets |

Plastic/ Non Woven Shower Cap Production Process

Using this shower cap machine can complete the steps of raw material entering, folding, welding, forming, and cutting at one time. Please check the following video for the specific production process provided by the YG plastic processing machine manufacturer.

Machine Details

PE CPE Bouffant Cap Machine Features

- Fully automatic operation, stainless steel structure, independent electrical control box.

- The surface parts are all chrome-plated, and the covering parts are made of stainless steel.

- Ultrasonic welding can be adjusted at will, and the production speed can be adjusted according to actual needs.

- One machine with multiple functions can produce strip caps of various specifications by changing different molds.

- The raw material can be PE plastic or non-woven fabric, and the production is flexible and diverse.

- High mold hardness, longer service life.

- Polyester nitrile rubber high-temperature-resistant rubber-coated rollers ensure smoother operation of the machine.

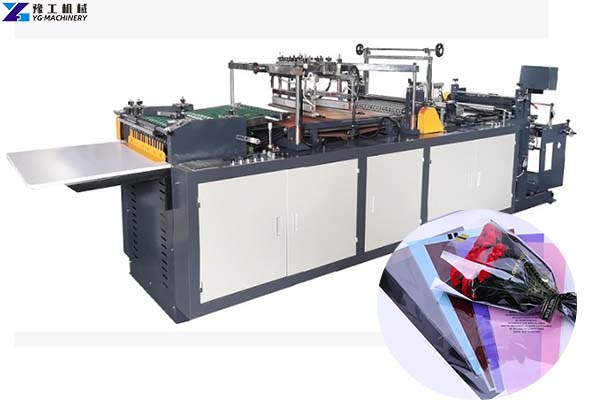

Related PE Products Machine

PE plastic machine is a general term for processing PE raw materials into various finished products. According to different finished products, YG plastic machinery manufacturer provides disposable shoe cover making machines, plastic apron making machines, flower sleeve bag making machines, long sleeve glove making machines, etc. If you are interested in YG’s PE product production equipment, please give We leave a message.