Bag on roll machine is an equipment for making continuous roll point-off type plastic bags. The equipment can be used to produce various types of continuous roll plastic bags, such as continuous roll garbage bags, pet bags, food bags, ice bags, etc. YG bag on roll making machine manufacturer offers various styles of polythene roll making machines, including semi-automatic, fully automatic, cored, and coreless. They meet the different needs of customers. If you want to know the price of the bag on roll machine, please contact us.

Introduction of Roll Bag

The continuous roll bag is a kind of bag that is connected by many packaging bags with a breakpoint in the middle, which can be torn apart by hand. The bag on roll is very convenient to store and use, and the point-off design ensures that every customer gets a clean bag. Therefore, this kind of continuous roll bag is very popular in supermarkets, and we can often see it in supermarkets. In fact, even roll bags have many other styles.

Rolling Bag Style

Our common continuous roll bags are the white and transparent bags in supermarkets for holding food and items. In fact, even roll bags have other styles and uses. For example, continuous roll pet garbage bag, vest bag, inflatable bag, garbage bag, string bag, ice cube bag, apron bag, etc.

Bag On Roll Machine Models

Continuous roll bag making machines are available in a variety of models and types. Depending on the degree of automation, there are two types of bag-on-roll machines: semi-automatic and fully automatic. For the production of core and coreless continuous roll bags, it can be divided into core and coreless continuous rolling bag making machines.

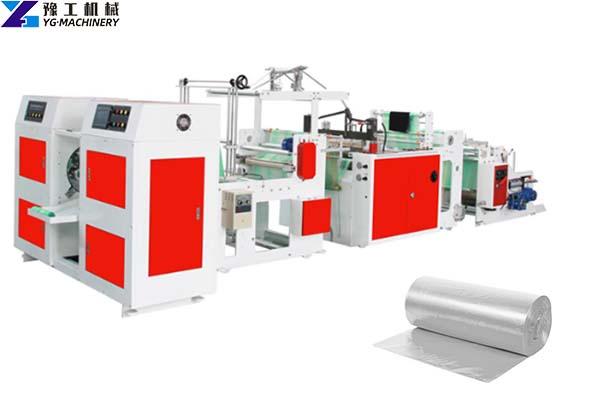

Fully Automatic Bag On Roll Making Machine With Core

- Dual channel heat sealing, hot cutting, core winding.

- Automatic counting, automatic roll change, synchronous feeding of double rubber rollers.

- Applicable to various color printing or natural color plastic film.

- Feeding to finished product at one time.

| Model | YG-450 |

| Bag making length | ≦800MM |

| Bag making width | 200~400MM |

| Bag making thickness | 0.008~0.15MM |

| Bag making speed | ≦300pcs/min*2 |

| Pressure range | 2~6Mpa |

| Total power | 20KW |

| Voltage | 380V 50HZ |

| Machine weight | 3000KG |

| Machine size | 6.45*2.05*1.6M |

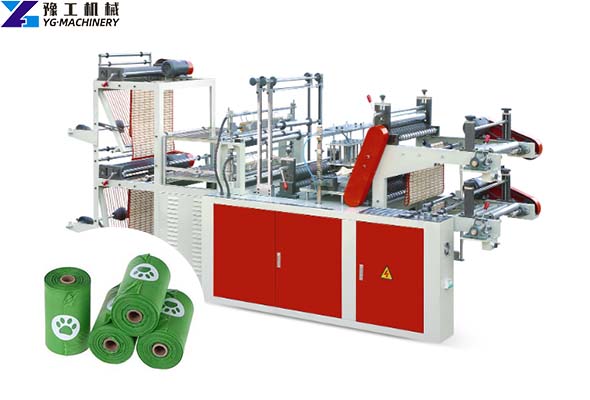

Fully Automatic Coreless Rolling Bag Making Machine

- Servo motor, automatic computer control, automatic production of coreless continuous roll plastic bags.

- When the film is exhausted, production is automatically stopped to reduce waste.

- When printing color errors or errors, the machine automatically stops production.

- Bag length and bag making speed are controllable.

| Model | YG-300 |

| Bag making length | ≦1200MM |

| Bag making width | ≦300MM |

| Bag making thickness | 0.015~0.15MM |

| Bag making speed | ≦300pcs/min*2 |

| Pressure range | 2~6Mpa |

| Total power | 20KW |

| Voltage | 380V 50HZ |

| Machine weight | 3000KG |

| Machine size | 6.45*2.05*1.6M |

Semi Automatic Core Bag On Roll Machine

- Double servo motor control system, inverter control, more stable production.

- Automatic counting, core winding, manual rewinding

- After feeding, break and seal at the same time, automatic film replenishment, no tension adjustment.

| Model | YG-450-2 |

| Bag making length | ≦1200MM |

| Bag making width | ≦400MM |

| Bag making thickness | 0.015~0.15MM |

| Bag making speed | ≦300pcs/min*2 |

| Pressure range | 2~6Mpa |

| Total power | 13KW |

| Voltage | 380V 50HZ |

| Machine weight | 2000KG |

| Machine size | 5.4*2.07*1.25M |

Semi Automatic Bag On Roll Making Machine Without Core

- The computer-controlled step-by-step fixed-length

system makes the sealing and cutting size error small. - The electric eye tracking device makes the position of the printed bag pattern accurate.

- Computer numerical control adjusts bag length and production speed.

| Model | YG-400 |

| Bag making length | ≦1000MM |

| Bag making width | ≦400MM |

| Bag making thickness | 0.005~0.15MM |

| Bag making speed | 120~300pcs/min |

| Pressure range | 2~6Mpa |

| Total power | 6.5KW |

| Voltage | 380V 50HZ |

| Machine weight | 1000KG |

| Machine size | 4.7*1.82*1.25M |

Machine Details

Polythene Roll Making Machine Features

- The applicable raw materials and product range are very wide. The suitable materials are high-density polyethylene, low-density polyethylene, cored, and coreless continuous roll bags.

- It can only be controlled by PLC double servo motors to realize automatic counting, automatic roll change, point breaking, sealing, and other steps.

- Suitable for the production of printing or non-printing continuous roll bags

- There are a variety of automatic and semi-automatic equipment options to meet the needs of different customers.

- The automatic feeding device is adopted, and the connection with the host can match the speed of the host, and automatic adjustment can be realized without manual operation.

- Installed with an alarm device, if there is any problem in the production process, it can automatically stop and sound an alarm.

Choose the Best YG Bag On Roll Machine Manufacturer

As a plastic bag making machine manufacturer, YG offers a variety of continuous roll bag making machines. The rolling bag making machine class we provide can produce continuous roll garbage bags, vest bags, air bags, string garbage bags, and other forms of on-roll bags. Besides, YG also provides other plastic bag making machines. Click on the plastic bag making machine page below to view the specific details. Or you can leave a message to YG to get the bag on machine price.