6 color dry offset printing machine is a kind of equipment that adopts advanced six-color printing technology to print exquisite patterns and texts on the curved surface of cups. The machine not only displays colorful visual effects but also perfectly fits various cup shapes, such as cylindrical and conical. This ensures the integrity and clarity of the pattern. Six-color curved surface printing cups are widely used in many fields, such as food, beverage, and advertising.

Parameters of 6 color dry offset printing machine

| Model | YG-6C |

| Printing Diameter Of Cup | Φ50-180mm |

| Printing Height Of Cup | Φ30-160mm |

| Max. Printing Depth | 160mm |

| Cup Body Slope | 5-15degree |

| Max.Printing Speed | 300-400cups/min |

| Main Motor Power | 7.5kw |

| Rubber Length | 4 or 2 Segment |

| Rubber Thickness | 2mm |

| Printing Plate Thickness | 1mm |

| UV Lamp Solid Power | 6kw |

| Corona Power | 1kw |

| Total Power | About 20kw |

| Weight | About 7T |

| Dimension ( L*W*H ) | 6.5m*2.5m*2.7m |

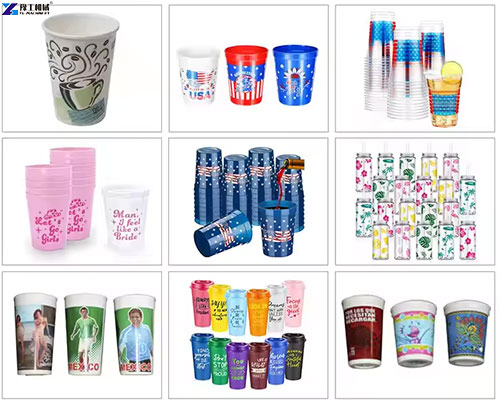

Applications of dry offset machine

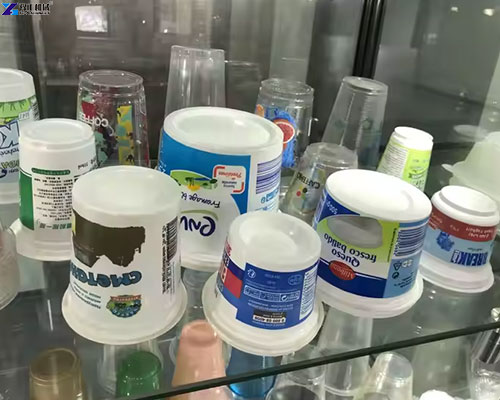

- Many specific cups can be printed: This equipment mainly prints color on the outside of the utensils. Items that can be printed include milk tea cups, cheese cups, yogurt cups, ice cream cups, soy milk cups, breakfast porridge cups, bowls, plastic bowls, instant noodle bowls, foam cups, and other plastic products.

- Application industry: The machine is mainly applied to graphic printing on the surface of rubber/plastic/glass/metal items for daily use, daily chemicals, color cosmetics, food, wine, medicine, etc.

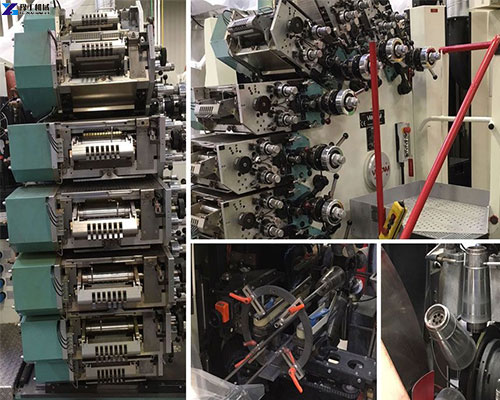

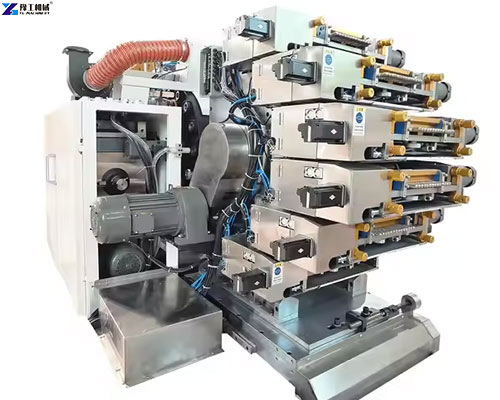

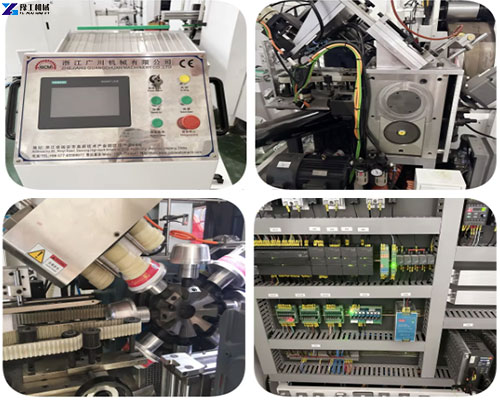

6 color offset printing machine details show

Each part of the six-color dry offset printing machine is reasonably structured, with high-quality materials and components that fit perfectly. The final result can realize a beautiful and flawless printing effect. Here is the detailed display of the machine, YG guarantees to provide you with high-quality printing equipment to help you start your own printing business smoothly. Last month our 6 color offset printing machine exported to Spain. The customer was very satisfied after receiving the equipment. The machine is of good quality and the printing effect is very good. He hopes to maintain a long-term cooperative relationship with us! We will provide you with comprehensive after-sales service. Welcome to consult our equipment!

dry offset cup printing machine’s workflow

- Preparation stage: machine ready, check and confirm cartridges, plates, tanks, air pressure, and safety devices.

- Start-up and initialization: start the machine, check, and warm up automatically.

- Cleaning and commissioning: clean the plate and rubber cylinders, and adjust the color.

- Feeding & Positioning: cups are automatically transferred and accurately positioned.

- Printing process: a flexible letterpress plate and rubber cylinder work together to print the graphic onto the cups.

- Curing and discharging: UV curing the graphic, and the discharging system collects and organizes the cups.

- Wrap-up and clean-up: turn off the machine, clean the parts, and replenish the consumables.

7 Features of Curved Surface Printing Offset Press

- The machine adopts the horizontal cup-feeding method, which makes the cup-feeding smoother. Pre-printing electric ironing treatment, clear and real printing.

- The main motor of the machine adopts three-phase frequency conversion speed control, synchronous belt drive, smooth running, and no noise.

- The ink supply is adjustable, and the pressure of the ink leveling roller is easy to adjust and ideal for the ink supply.

- Each ink transfer group is an independent transmission mode and can be controlled separately. This can save electricity and reduce mechanical wear and tear. Increase the service life of the machine.

- The printing plate is installed as a sticky plate type, which can greatly save the printing plate fee, easy to set the color of the plate.

- The printing roller and plate roller are cantilevered, easy, and reliable to adjust the pressure.

- Automatic cup collection after printing, UV curing at die head station, automatic shading function, safe and reliable.

six-color curved cup printing machine from YG

YG is the leading manufacturer of six-color curved cup printing machines. We are committed to providing efficient and intelligent curved surface printing solutions for customers worldwide. Through continuous innovation and time, YG has created a wide range of high-precision and high-efficiency curved cup printing machines that are perfectly suited for a wide range of materials and shapes of cups. The printing machine adopts an advanced servo system and environmentally friendly ink, which ensures the machine is both intelligent and green. We also provide multi-color PP woven bag printing machines, flexo printing machines, digital printing machines, GRC spraying machines, polyurethane spraying machines, and other equipment. Tell us what you need and get the factory price for 6-color curved printing machines!