Recently, a Ghanaian entrepreneur decided to enhance his egg farming business by investing in an advanced egg carton machine. This purchase marked a significant step towards improving packaging efficiency and reducing costs. The client, recognizing the potential of automated machinery, opted for a state-of-the-art model that combined robustness with precision. The egg carton machine he selected was designed to cater specifically to the needs of the African market, ensuring high-quality output tailored to local conditions.

Specifications of the Egg Carton Machine

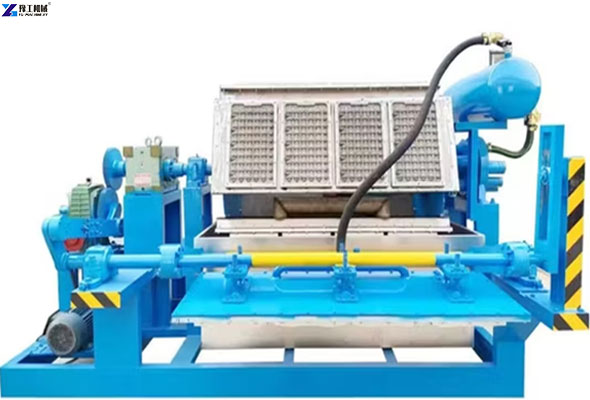

The chosen egg carton making machine boasts impressive specifications, including a high production capacity and customizable mold options. It is a paper molding machine that utilizes recycled paper materials, making it environmentally friendly. With dimensions optimized for space-saving, this egg tray maker machine ensures smooth operation and minimal downtime. The machine is also equipped with advanced control systems, allowing for precise adjustments to meet varying egg sizes and packaging requirements.

| Model | YG-1*3 | YG-1*4 | YG-3*4 | YG-4*4 | YG-4*8 | YG-5*8 | YG-6*8 |

| Capacity (pcs/h) | 1000 | 1500 | 2500 | 3500 | 4500 | 5500 | 7000 |

| Forming Mould Quantity | 3 | 4 | 12 | 16 | 32 | 40 | 48 |

| Total Power (kW) | 40 | 40 | 50 | 60 | 130 | 140 | 186 |

| Electricity Consumption (kw/h) | 28 | 29 | 35 | 42 | 91 | 98 | 130 |

| Worker | 3-5 | 4-6 | 4-6 | 4-6 | 4-6 | 5-7 | 6-8 |

Why customer Purchase A Paper Moulding Machine?

The Ghanaian customer decided to purchase the pulp egg tray machine based on the following practical considerations:

- First, by independently producing pulp egg trays, it will reduce the egg packaging cost. And also increase the profit margin.

- Secondly, the pulp egg tray machine allows customers to customize egg trays with unique logos, enhance product recognition, and thus stand out in the fiercely competitive market.

- Furthermore, pulp egg trays’ raw materials are waste paper. It is both environmentally friendly and economical, meets the current consumer demand for green packaging, and helps to enhance the corporate image.

- Finally, the high production capacity of the pulp egg tray machine provides a solid foundation for future business expansion, ensuring that the demand for egg packaging can be easily met as production increases.

Benefits of using an egg tray machine for African customers

1. Economic benefits

Low-cost raw materials: Waste paper is the main raw material of pulp egg trays. It is relatively easy to obtain in Africa and low-cost, which helps to reduce production costs.

2. Environmental advantages

Degradability: The raw material of pulp egg trays is waste paper, which realizes the recycling of waste. Therefore, the pulp egg trays are also environmentally friendly and easy to degrade naturally.

3. Product performance

The design of pulp egg trays can effectively fix and protect eggs, reduce the breakage rate during transportation, and improve product quality.

4. Versatility

In addition to being used as egg packaging, pulp egg trays can also be used for many other purposes, such as planting small plants, as insulation pads, storing small items, etc., reflecting their versatility and practicality.

YG Offers Customizable Egg Tray Maker Machine

YG Machinery, the supplier, specializes in providing customizable egg carton-making machines tailored to client needs. Understanding the uniqueness of each market, YG offers flexible solutions, from basic models to fully automated systems. Additionally, YG’s expertise extends beyond egg cartons, encompassing machinery for one-time-use items like paper cups and plastic bottles through blow molding machines, demonstrating a comprehensive approach to packaging solutions.