A GRC spray machine is a device that can spray mixed materials such as cement, sand, glass fiber, water, and pigment! The surface of sprayed objects will be more beautiful and corrosion-resistant. We often use it in building exterior wall decoration, interior decoration, garden landscapes, GRC European-style components, and fireproof and waterproof material spraying. Click the button to get detailed information on the equipment!

GRC spray machine Parameters

| Product name | Glass Fiber Reinforced Concrete GRC Spray Machine |

| Power | 2.2-4.0kw |

| Voltage | 380v 50hz |

| Speed | 20-200r/min |

| Workspace | 4.5m |

| Delivery capacity | 300-1600kg/h |

| Production efficiency | 200-400m2/h |

| Volume | 60L |

| Dimension for the sprayer | 2000*1050*1600mm |

| Dimension for the mixer | 1550*1000*2100mm |

| Total weight | 800kgs |

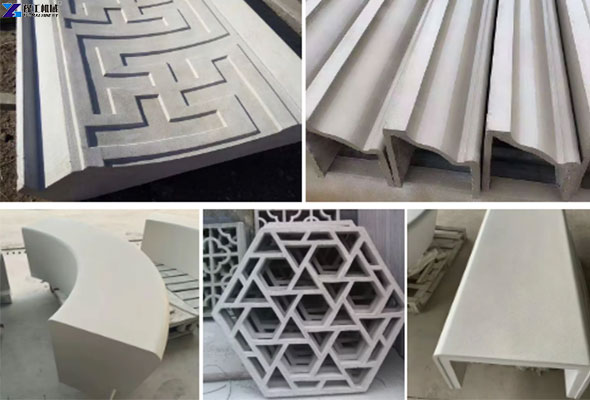

Scope of application of gRC machine

- GRC spraying machine is mainly used for GRC European-style components, indoor and outdoor wall decoration spraying, thermal insulation materials spraying, relief crafts paint spraying; small villas, clubs, bridges, dams, the guardrail, and other spraying spraying. The equipment is flexible and lightweight, with a wide range of uses.

- Adaptation of spraying materials: GRC mixed glass fiber chopped wire(Medium alkali, Alkali-free, Alkali-resistant), gypsum, magnesium oxide cement, relief effect paint. We will recommend the appropriate raw material according to your needs.

5 Features of the GRC Spraying Machine

- The spraying machine feeds the material uniformly, without an obvious pulse, for the machine spraying GRC products with a uniform ratio.

- The machine product adopts standardized components, reasonable design, compact structure, small volume, and easy disassembly and maintenance.

- GRC spraying machine adopts stepless speed control technology to adjust the flow rate and realize a better spraying effect.

- The working area range of the equipment is large. The horizontal swivel arm diameter of the spray gun and feeding hose is up to 10 meters. Together with the hose, the working area can be up to 120 square meters.

- GRC spraying machine has high construction efficiency, good quality, easy-to-purchase accessories, and low cost.

GRC Mortar Spray Machines Working principle

The working principle of the GRC sprayer is mainly based on the synergy between the liquid pump and the motor.

- The liquid pump conveys the mixed GRC material under pressure to the spray gun, and the motor drives the liquid pump to rotate, generating enough pressure to spray the material out.

- Then a regulating valve will control the flow of the material and the shape of the spray. The nozzle size and operating speed will determine the spray shape.

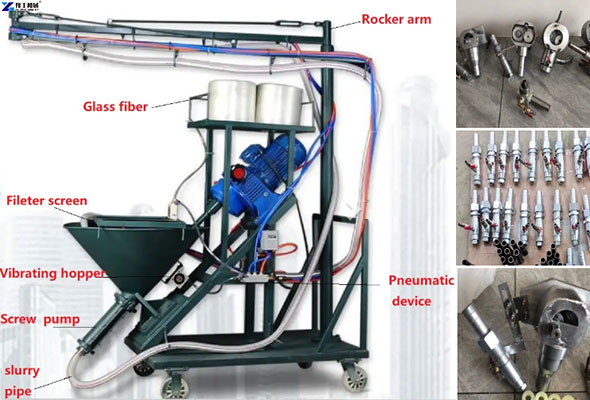

GRC fiberglass spraying machine structure and Accessories

GRC fiberglass spraying machines mainly have a rocker arm, glass fiber, filter screen, vibrating hope, pneumatic device, screw pump, slurry pipe, etc. We also provide various machine spare parts. High quality, affordable price, and comprehensive service have helped us gain many domestic and foreign customers. Click to tell us your needs and we will provide you with a detailed machine quotation! It includes all accessories. Please consult us now!

GRC fiberglass spraying machine from YG

YG has a strong production capacity, and we can produce large quantities of GRC spraying machines in a short period. We can satisfy the needs of customers who purchase in large quantities. Now our GRC sprayers have been sold to Oman, India, the United Arab Emirates, the USA, the Philippines, Saudi Arabia, Qatar, Thailand, Malaysia, Australia, and many other countries. The short cycle time, good quality, and low cost of making GRC products can help users get good economic benefits faster. Contact us to get a free quote for your equipment!