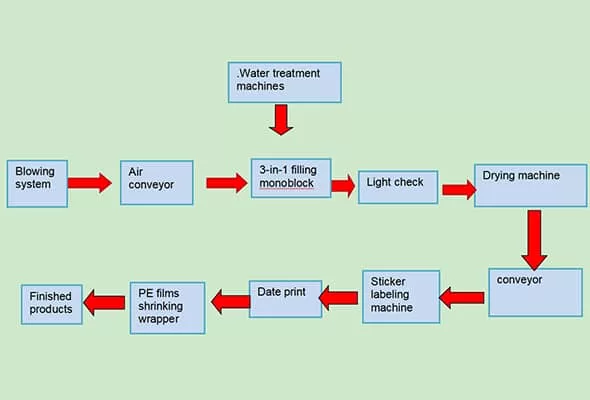

YG’s mineral water filling machine equips with a mineral water bottle blowing machine that can realize the automatic process of blowing and filling. This automatic mineral water packing machine is a three-in-one filling machine for bottled water filling. Its rinsing, filling, and capping are all concentrated on one machine, and the whole process is fully automated. The mineral water filling machine adopts a new micro-pressure filling method, with fast filling speed and large output. The following will introduce the water bottling line for you by taking mineral water with a capacity of 500ml and a capacity of 3000BPH as an example.

Mineral Water Bottle Filling Solution

Capacity: 3000BPH (500ml)

Application: pure water, mineral water, juice, fruit wine

Function: bottle rinsing, filling, capping

Supporting equipment: water treatment system, mineral water bottle making machine, labeling machine, air drying machine, inkjet printer, shrink film packaging machine.

3000BPH(500ml) mineral water filling machine list

| No | Machine name | Model | Qty |

| 1 | Air conveyor | FS-1 | 6m |

| 2 | Conveyor System Inc. motors | Capapcity:3000BPH(500ml)Washer;8,Filler:8,Capper:3 | 1set |

| 3 | Automatic cap elevator | Conveyor type | 1set |

| 4 | Conveyor System inc. motors | SS-1 | 10m |

| 5 | Light checker | DJ-1 | 1set |

| 6 | Dryer machine | CGJ-1 | 1set |

| 7 | Laser printing machine | DMJ-1 | 1set |

| 8 | Automatic sticker labeling machine(single side) | DLT-2capacity is 3000BPH | 1set |

| 9 | Automatic water bottle shrink Wrapper machine | MBJ-1 | 1set |

The mineral water filling plant takes the mineral water filling 500ml bottle as an example, and the filling output per hour is 3000 bottles. The filling equipment involved includes conveyor belts, filling machines, cap lifters, dryers, labeling machines, shrink film packaging machines, and other equipment. All the above equipment are not standardized configurations, YG can match the corresponding filling equipment according to the needs of different customers.

Automatic Mineral Water Bottling Line Introduction

According to the above mineral water bottling line list, the following is a detailed introduction for you.

Conveyor belt

The conveyor belt is mainly used to place and transport mineral water bottles. The front end of the conveyor belt connects to the mineral water bottle making machine.

| Item | Technical parameter |

| Centrifugal blower | DF-1 |

| Power | 1.5Kw*1SET |

| Air pressure | 1210Pa |

| Air quantity | 1200m3/h |

| Voltage | 380V/50Hz |

| Air conveying channel is made of SUS304 | Length 2 M |

3 in 1 mineral water bottle filling machine

3 in 1 mineral water bottle filling machine integrates three functions washing, filling, and sealing. It applies to filling mineral water, pure water, fruit juice, and other products. It adopts bottleneck clamping transmission technology, which can fill bottles of various specifications.

| Item | Technical parameter |

| Type | XGF8-8-3 |

| Capacity | 3000BPH at 500ml; |

| Filling material | Drinking water |

| Locate mode | Liquid level |

| Weight | 1500KG |

| Size | 1800x1550x2000mm |

| Bottle application | Electric motor →triangle belt transmission→ worm reducer |

| Conveyor form | Air conveyor |

| Driving type | Electric motor →triangle belt transmission→ wormreducer |

Bottle cap feeding machine + capping machine

The bottle cap feeder is a device used to transport bottle caps from a lower position to a higher position. This equipment is the best auxiliary equipment for the capping machine. The capping machine conveys the bottle caps according to the number of times, places them on the mineral water bottles, and then caps them. The capping machine can be used for plastic caps, aluminum caps, crow caps, etc.

| Item | Technical parameter |

| Fan | 380V, 0.55KW |

| Motor | 380 V,60W |

| Size | 700×700×3050mm |

Light checker

Light check is used to check whether there are impurities in the product.

| Item | Technical parameter |

| Type | DJ-1 |

| Power | 40w |

| Dimension | 800*130*300mm(L*W*H) |

| Usage | To check the filled bottles |

Blow Dryer

The blow dryer uses a high-pressure blower to blow off the water on the bottle. The equipment is mainly composed of high-pressure blower, blowpipe, frame, control device, pressure-stabilizing tank, and so on.

| Item | Technical parameter |

| Type | CGJ-1 |

| Material | SUS304 |

| Air wind machine | 1 sets, Automatic |

| Power | 5.5KW |

| Size | 1500×600×1800mm(L*W*H) |

Laser printing machine

The laser printing machine prints various signs such as numbers and text on the bottle body.

| Material | All aluminum construction |

| Laser | Enclosed metal radio frequency carbon dioxide laser generator |

| Continuous output power | 20W |

| Laser wavelength | 10.6um |

| Deflecting mirror | High-integrated motherboards, built-in 7-inch screen |

| Marking speed | ≤10000mm/s |

| Master control | High-integrated motherboards, built-in 7 inch screen |

| Operating system | WIN CE |

| Cooling system | Wind cooling |

| Focus camera | Focal length 130mm |

Labeling machine

The labeling machine is controlled by a microcomputer touch screen and is mainly used to stick stickers on the bottle body.

| Name | Automatic Round Bottle Sticker Labeling Machine |

| Model | Round or cylinder shape bottles; PET or glass bottles |

| Objects | The maximum outside diameter of the label roll |

| Maximum outside diameter of the label roll | 380mm |

| Label roll | Inner diameterφ76 mm ,Outer diameter Max φ350mm |

| Precision | ±1.5mm |

| Capacity | 0-21m/min(Adjustable) |

| Voltage | AC 220V,50/60Hz. |

| Power | 500W. |

| G.W. | 300Kg. |

| Dimension | L2000 ×W900×H1400 mm |

Water Bottle Shrink Wrapping Machine

The water bottle shrink wrapping machine is suitable for packaging single or multiple mineral water bottles with shrink film. It is designed for film sealing and heat-shrinking packaging equipment.

| Input Power | 12Kw |

| Can supply | 380V,3N,50Hz |

| capacity | 8-10 Packs/min |

| Dimension | 5050L×3100W×1800mmH |

| Can bottles diameters | 25mm~120mm |

| Can labels length | 30mm~250mm |

| Height of Conveying Belt | 750mm~1100mm |

| Working Pressure | 0.6~0.8Mpa |

| Can films | PE |

Conveyor belt

The conveyor belt can realize frequency conversion speed regulation. And the speed of the conveyor belt can be automatically adjusted according to the output produced. The shape and length of the conveyor belt can be customized according to customer needs.

| Production capacity | 3000 bottles/hour |

| Chain plate | Lex Technology |

| Electrical components | OMRON |

Composition Of Mineral Water Packing Machine

The mineral water packing machine includes six systems, they are washing, filling, capping, driving, feeding, and electrical control.

- Flushing system: flushing claw plate, water diversion plate, sink

- Filling system: liquid tank, filling valve, control ring, upgrade cylinder

- Capping system: capping machine, cap unscrambling machine, cap dropping guide device

- Drive system: gear drive, main motor, gear

- Feeding system: guide plate, star wheel, conveyor chain

- Electrical control system: frequency conversion speed regulation, PLC, touch screen operation

Mineral Water Filling Machine Features

- The whole machine adopts PLC computer program control and human-machine interface touchscreen buttons.

- It adopts the latest technology at home and abroad and applies the principle of pressure-type constant liquid level filling. The filling is accurate and there will be no dripping.

- Automatic control of the pages in the material tank, no bottle, no filling, no bottle, no capping, and other functions.

- The mineral water filling machine has a variety of specifications, which can realize the filling of various outputs. It meets the needs of customers with different specifications.

- It has the characteristics of high filling efficiency, high reliability, easy maintenance, and operation.

Other Filling Solutions

YG plastic bottle manufacturers provide customized filling solutions for different customers. The following are the filling solution that our customer inquiry mostly.

- 1000-2000BPH small water bottle-filling machine

- 8000BPH Water Filling Line

- water packet machine

- 1 ltr water bottle packing machine

- 1.3.5 gallon water filling machine

- pure water filling machine

- pet bottle-filling machine

In addition, YG also provides water treatment systems, plastic bottle making machines, film blowing machines, plastic bag machines, injection molding machines, and other plastic equipment.