The plastic straw making machine is also called a drinking straw extrusion machine, which extrudes plastic straws through a mold. There are many materials for plastic straws, such as PP material and PLA material. YG plastic machinery manufacturer also provides single-color, double-color, and multi-color co-extrusion machines to make various types of plastic straws. The PP PLA straw extruder machine also can combine with a vacuum cooling tank, high-speed tractor, cutting machine, and drinking straw packing machine to form a plastic extrusion line.

Plastic Straw Type

With the development of the food and beverage industry, there are more and more types of straws. The common ones are PP material straws, PLA material straws, and paper straws. Traditional plastic straws use PP material, which is a transparent material. Color masterbatches can also be added to make straws of different colors and lines during production. As people’s requirements for environmental protection are getting higher and higher, straws made of PLA-degradable materials are also widely used. Since the plastic straw extruder relies on molds to make straws, it can also replace other molds to make label tubes, sugar sticks, toy tubes, etc.

Related Machine

PET Bottle Making Machine

Plastic Drinking Straw Making Machine Model

| Model | Screw diameter | Screw aspect ratio(rpm) | Main motor power | Automatic temperature control area | Cooling device | Traction cutting power | Specification |

| Single-color straw machine | 50mm | 28:1 | 11KW*1 | 5 | 6 meters cooling water tank | 0.75kw*2 | 1mm-9mm |

| Single color straw machine | 55mm | 28:1 | 15KW*1 | 5 | 6 meters cooling water tank | 0.75kw*2 | 1mm-13mm |

| Two colors straw machine | 50mm*1 25mm*1 | 28:1 | 11KW*1 0.75KW*1 | 7 | 6 meters cooling water tank | 0.75kw*2 | 1mm-9mm |

| Two colors straw machine | 55mm*1 25mm*1 | 28:1 | 15KW*1 0.75KW*1 | 7 | 6 meters cooling water tank | 0.75kw*2 | 1mm-13mm |

| Three colors straw machine | Single-color straw machine | 28:1 | 11KW*1 0.75KW*2 | 9 | 6 meters cooling water tank | 0.75kw*2 | 1mm-9mm |

| Three colors straw machine | 55mm*1 25mm*2 | 28:1 | 11KW*1 0.75KW*2 | 9 | 6 meters cooling water tank | 0.75kw*2 | 1mm-13mm |

Remarks: The above is just a reference, please send us the specific style and size of the straw you want to make, and we will provide you with a suitable model.

Plastic Straw Production Process

The production process of plastic straws mainly includes extrusion molding, cooling, pulling, cutting, and other steps. First, put the plastic into the plastic straw extruder to melt, and the melted plastic is formed through the mold of the port. After being cooled by the cooling pool, the continuous straw is drawn to the cutting machine for cutting. The cut straws are packaged and finished.

Drinking Straw Extrusion Line

The beverage straw extrusion production line mainly includes an extruder, mold, cooling water tank, tractor, cutting equipment, and so on. Plastic Straw making machines include single-color, double-color, three-color, four-color, and other models.

Application: It can produce beverage straws, toothpicks, candy bars, ballpoint pen refills, industrial sleeves, drip tubes, etc.

Plastic Straw Extruder

In the straw extruder, the plastic is melted and shaped through an extrusion die. The equipment has a good plasticizing effect, stable extrusion, and low energy consumption.

Plastic Straw Mold

The extrusion die adopts imported S136 steel, and the extrusion size is stable. Support custom molds of different molding shapes and sizes.

Vacuum Cooling Water Tank

The vacuum cooling water tank uses imported stainless steel, a tempered glass cover plate, and a three-dimensional mobile design.

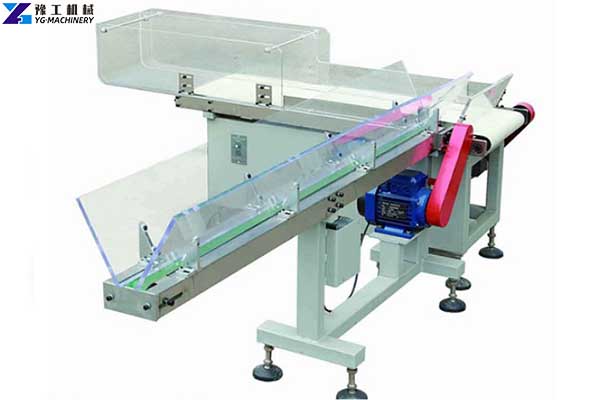

High-speed Tractor

The high-speed tractor guides the cooled plastic straws to the cutting machine. The tractor has high-speed traction and stable performance.

Plastic Straw Cutting Machine

The high-speed cutting machine cuts the continuous plastic straws to the same length, with precise cutting, adjustable length, and flat cut.

Straw Tube Machine

A straw tube machine is used for the automatic arrangement of straws, neatly placed and efficient production.

Plastic Straw Packing Machine

The plastic straw packaging machine packs single or multiple straws.

Plastic Straw Making Machine FAQ

Not the same. Due to the material properties of the PLA straw, in order to improve the high-temperature resistance of the PLA material, it is necessary to make the PLA straw more round and more resistant to high temperature through secondary crystallization. Therefore, it requires a special PLA straw-making machine to make PLA straws.

It can produce pipes of PLA, PHA, PP, PE, and other materials.

OK. We support the voltage change service and replace the machine voltage according to the customer’s local voltage requirements.

Yes. Molds of different specifications and shapes can be customized.

No, it can also be used to produce various PP PE pipes, such as pen core tubes, balloon support tubes, water purifier tubes, shampoo pump head tubes, face sticks, etc.

All the machines in this plastic straw production line are already installed before leaving the factory. If you have installation needs, we can also send our engineers to your local area.

Yes, YG also provides straw bending equipment, which is secondary processing equipment for drinking straws.

Related Equipment: Paper Straw Making Machine

In addition to plastic straw making machines, YG also provides paper straw machines. It is suitable for miniature small-diameter paper tubes, such as ballpoint pen tubes, bobbin tubes, paper straws, milk tea straws, etc. The paper straw-making machine supports a size with an inner diameter of 5mm-12mm, and can only be controlled by PLC, and the entire production process is automated.