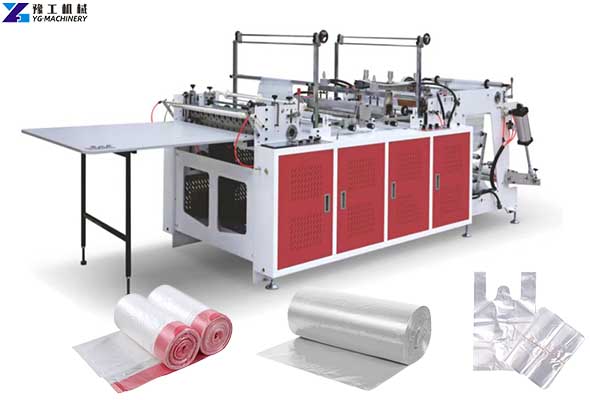

The PP woven bag making machine is a special equipment used to process PP raw materials to produce plastic woven bags. It is also called PP woven bags manufacturing plant because it contains many types of equipment for processing woven bags. The PP woven bag making machine makes PP raw materials into woven bags through drawing, circular weaving, cutting, bag sewing, packing, and other processes. The produced woven bags can be used in many fields such as agriculture, industry, and transportation.

Finished Woven Bag Display

PP Woven Bag Making Machine Youtube Video

How are Woven Bags Produced?

The production of woven bags has roughly gone through processes such as drawing, circular weaving, cutting, sewing bags, and packing. Plastic woven bags are divided into non-laminated plastic woven bags and laminated plastic woven bags. There are certain differences in the production process of these two plastic woven bags. The non-laminated woven bag has been printed, cut, and sewn into a woven bag. The composite plastic woven bag needs to be compounded or coated first, and then the tube cloth is cut, printed, stitched, and other processes to make a woven bag.

PP Woven Bag Making Machine Details

Woven Bag Wire Drawing Machine

The wire drawing machine can use recycled plastic bottle flakes, powder, or pellets to draw flat wire. The PP PE flat wire produced by this wire drawing machine is widely used in the weaving of woven bags, sunshade nets, earth-covering nets, and net bags. The production process of the wire drawing machine is plastic pellets, heating and extrusion, cooling and forming, automatic wire separation, heating and extension, secondary traction, and winding.

| Model | SJ-65 | SJ-80 | SJ-90 |

| Screw diameter (mm) | 65 | 80 | 90 |

| Screw speed ( r/min) | 30-70 | 30-70 | 30-70 |

| Stretch ratio | 1:5 | 1:5 | 1:5.5 |

| Installed capacity ( KW) | 40 | 60 | 78 |

| Productivity ( kg) | 40-60 | 60-80 | 80-125 |

| Machine size ( m) | 18×2.1×2 | 20×2.1×2 | 25×2.2×2 |

| Machine Weight (T) | 3.5 | 4 | 4.5 |

Circular Loom Machine

The circular loom machine is widely used in weaving mesh bags for packing vegetables and fruits. It is suitable for weaving flat yarns of various qualities, with good weaving quality and high production efficiency. It is the best equipment for enterprises to produce woven bags. According to different production capacities, it has four shuttles, six shuttles, eight shuttles, ten shuttles, and other different models.

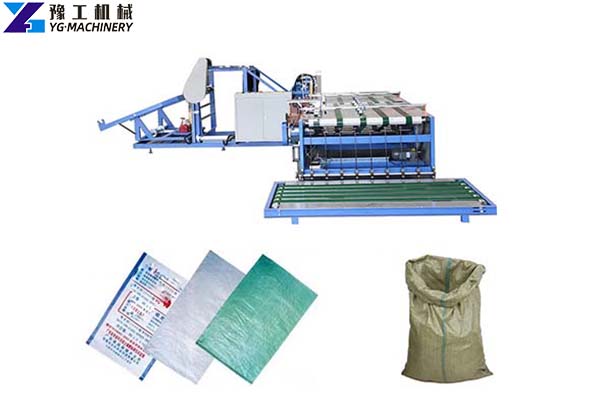

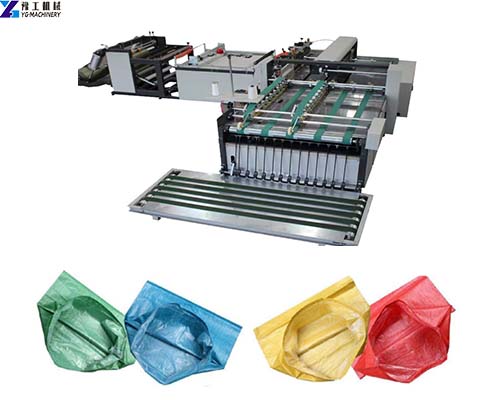

Woven Bag Cutting Sewing Machine

The tube cloth woven by the circular loom machine can be directly placed on the woven bag cutting and sewing machine for operation. After stitching, then use a PP bag printing machine to print the pattern, or print first, and then use an all-in-one machine to operate. The woven bag stitching machine integrates automatic feeding, automatic deviation correction, fixed-length cutting, seam bottom counting, bag collection, and other operations. In addition, YG also provides woven bag single sewing machines, woven bag cutting, sewing, and printing machine, woven bag printing machine, and other woven bag processing equipment.

| Model | YG-800 |

| Capacity | 40-55strip/min |

| Cutting range | 300-800mm |

| Max length range | 470-1280mm |

| Hem Width | 20-30mm |

| Pitch | 8-12mm |

| Weight | 2000kg |

| Machine size | 6*5.5*1.5m |

| Voltage | 220V |

| Power | 14.5kw |

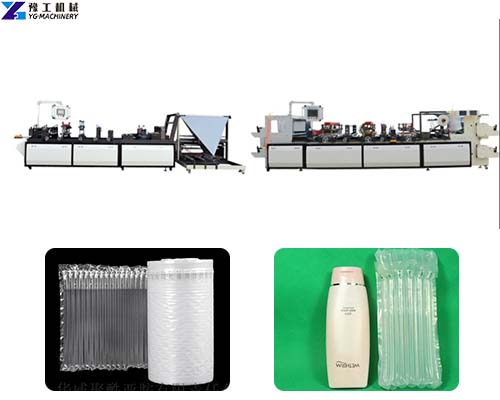

Plastic Woven Bag Custom Style

YG plastic woven bag making machine manufacturer provides woven bag style customization service. No matter what kind of woven bag sealing style you want to make, YG can meet your needs. Please send us the woven bag style you want to make, and we will recommend a suitable plastic bag making machine for you according to your needs.

How Much Does the PP Woven Bags Manufacturing Plant Cost?

The above has introduced you to the most important parts of the woven bag making machine. In actual production, in order to save the budget, many manufacturers will directly purchase the tube cloth and directly carry out the steps of cutting, sewing, printing, and so on. According to the needs of different manufacturers, the prices of woven bag making machines are also different. Moreover, the above-woven bag making machines can also be customized according to the needs of customers. So please contact us to get the Woven Bag Making Machine Price.

FAQ of Woven Bag Making Machine

The raw material for making plastic woven bags is generally polypropylene or polyethylene.

The finished woven bags made by the woven bag-making machine can generally be used for holding items in agriculture, industry, and transportation industries.

Yes, YG plastic woven bag-making machine manufacturers can customize the machine according to the needs of customers to help customers produce plastic woven bags.

Different customers have different needs. If you start production from raw materials, then you need wire drawing machines, circular looms, cutting and sewing machines, printing machines, and other equipment. If you buy tube cloth for production, you only need a woven bag cutting and sewing machine.

Please contact us and tell us your production needs, and we will match you with suitable production machines.

Because the equipment needs to be customized, the delivery time is generally within 7~25 days.

The warranty period for the machine is one year.